What is Signal Integrity (SI)?

Imagine you’re sending a message across town. In the world of electronics, that message is a tiny electrical signal traveling along a pathway. Signal Integrity (SI) is all about ensuring this message arrives at its destination clear and undistorted.

“Signal Integrity (SI) is a set of engineering principles concerned with maintaining the fidelity of this electrical signal as it travels from its source to its destination. It ensures the signal retains its intended strength, shape, and timing characteristics, allowing electronic devices to function as designed.”

Why Does SI Matter?

Think of SI as the quality of the road your message travels on. A smooth, well-maintained road (good SI) allows the message to arrive clearly. However, a bumpy, pothole-filled road (poor SI) can scramble the message, leading to errors and malfunctions in your electronics. This could mean anything from distorted audio on your phone to a complete system crash.

Here are some everyday problems that poor signal integrity can cause.

- Glitches on your computer screen: Distorted signals might show up as strange pixels or freezing images.

- Data errors during file transfer: A corrupted message can mean a failed download or a messed-up document.

- Unreliable wireless connections: Interference on the signal path can lead to dropped calls or choppy internet.

By understanding SI, we can build electronics designs that are reliable and efficient and deliver the clear communication we all depend on.

I. Fundamentals of Signal Integrity: Understanding the Journey of Your Signal

When talking about signals, electronics designs are built on the foundation of 2 different signals, namely Analog and Digital Signals.

- Analog signals: These are continuous variations in voltage, like the smooth rise and fall of sound waves. Imagine sending a message with the volume of your voice constantly changing. Poor SI can cause the baseline (average voltage level) of the signal to shift over time and can cause distortion.

- Digital signals: Digital signals represent information as discrete voltage levels (typically high for 1 and low for 0). Poor SI can cause these levels to become distorted or overlap, leading to bit errors. Imagine sending a text message where some letters get switched or lost due to a bad connection. This can corrupt data and cause malfunctions.

By affecting both analog and digital signals, poor SI can lead to a wide range of performance issues in electronics devices. These issues can manifest as:

- Reduced functionality

- Inaccurate measurements

- Unreliable data transmission

- Data corruption

- System instability

- Frequent crashes

Therefore, maintaining good SI is crucial for ensuring the reliable and efficient operation of electronic devices.

Transmission Lines: A Different Perspective

As signal frequencies increase, the way they travel on PCB traces changes. Imagine a highway designed for slow-moving cars suddenly filled with high-speed traffic. The traces start to behave like transmission lines, where the properties of the conductor itself (width, thickness, material) become critical.

One key concept to understand is impedance. Think of it as the resistance the signal encounters on the trace, similar to friction on a road. In a transmission line, a mismatch between the signal’s impedance and the trace’s impedance can cause reflections. Imagine bouncing a ball on a trampoline (low impedance) versus a thick carpet (high impedance). The high impedance path (carpet) will significantly weaken and distort the bounce (reflection) of the ball (signal).

Understanding transmission lines is essential for maintaining good SI in modern electronics, where high speeds are becoming the norm. By carefully managing the impedance of PCB traces, we can prevent reflections and ensure signals travel cleanly and efficiently.

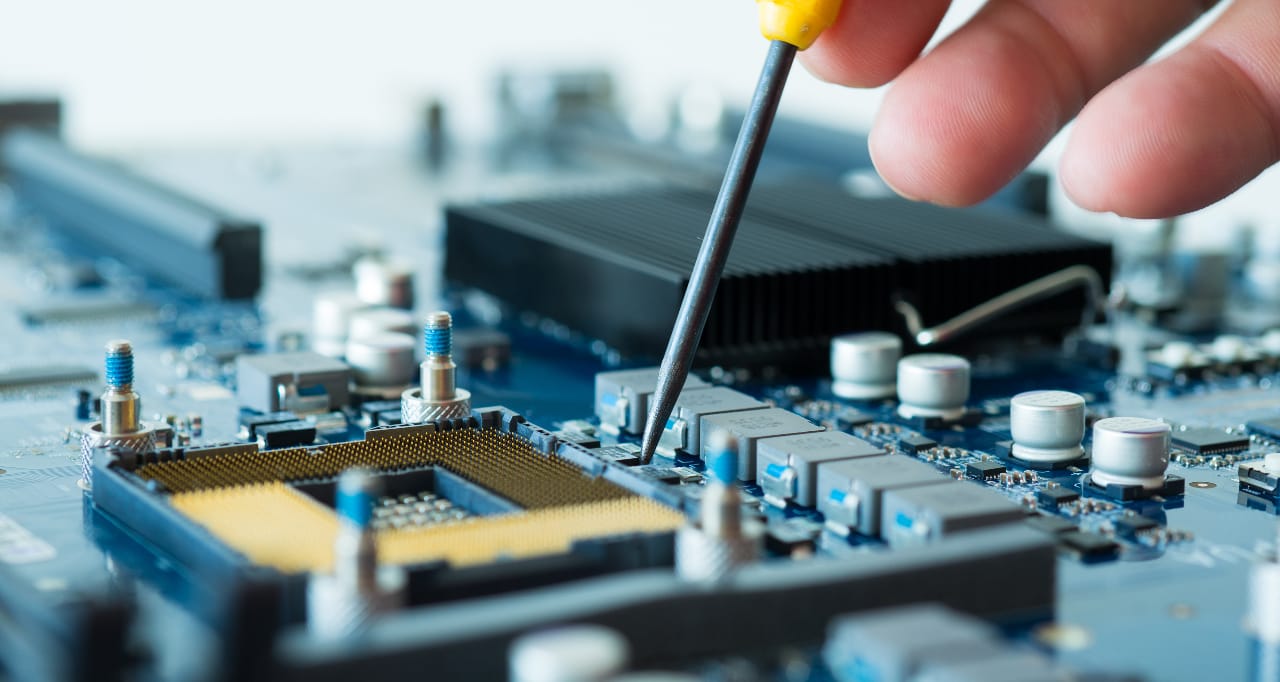

II. Maintaining Signal Integrity in PCB Design

No matter how good your electronics design is, its efficiency solely relies on Signal integrity. Following are some design techniques and tools that help you achieve robust SI in your PCB designs.

Design Techniques for Good SI

- Impedance Matching and Controlled Impedance Routing:

PCB traces act like transmission lines at high frequencies. Impedance is the opposition a signal encounters on the trace, similar to friction on a road. The mismatched impedance between the signal and the trace can cause reflections, distorting the signal. Controlled impedance routing involves carefully designing the trace width, thickness, and dielectric material to achieve a desired and consistent impedance throughout the trace length. This ensures the signal travels cleanly and efficiently.

- Proper Termination Techniques:

Even with controlled impedance routing, reflections can still occur. Termination involves placing a specific impedance (resistor) at the end of a trace to absorb these reflections, preventing them from bouncing back and interfering with the signal.

Engineers can use series or parallel termination, depending on the specification of the application.

- Grounding and Power Plane Strategies:

A stable reference voltage is crucial for maintaining SI. Ground planes on your PCB provide a low-impedance path for current to return and minimize noise. Strategies like star grounding (where all ground connections meet at a single point) and split power planes (separating digital and analog power supplies) further enhance signal integrity.

- Layout Practices for Minimizing Crosstalk:

When high-speed signals travel close together on a PCB, they can “talk” to each other, causing unwanted coupling (crosstalk). Here are some layout practices to minimize crosstalk:

- Maintain sufficient spacing between high-speed signal traces.

- Use differential routing for critical signals, where the signal and its inverse travel on closely spaced parallel traces, canceling out common-mode noise.

- Avoid sharp bends in traces, as they can introduce unwanted capacitance and increase crosstalk.

- Measurement Techniques for SI Verification:

While simulations are invaluable, physical measurements are essential for verifying the performance of your final electronics PCB design. These measurements ensure your design meets the required SI specifications and functions as expected in the real world.

Common measurement tools used for SI analysis include:

- Oscilloscopes: allow you to see the ups and downs, or voltage changes, of electrical signals in real time. They display the signal as a graph on a screen. The horizontal axis represents time, and the vertical axis represents voltage. By monitoring these graphs, you can detect noise, reflections, and other SI issues.

- Vector Network Analyzers (VNAs): VNAs measure the magnitude (strength) and phase (timing and direction) of signals. They also determine the impedance mismatches of PCB traces.

With a bit of planning and the right tools, engineers can make sure that their electronics designs will achieve optimal signal integrity with reliability and efficiency.

III. Troubleshooting SI Challenges: A Practical Guide

Even the best electronics designs can sometimes have signal problems. Don’t be blinded by the glitches. Here are some common symptoms to watch out for:

- Digital Signals: Increased bit error rate (BER) can lead to data transmission errors, causing malfunctions or unexpected behavior in your system.

- Analog Circuits: Unexpected fluctuations in performance or erratic signal behavior can indicate SI issues affecting the delicate analog signals.

- Signal Quality: Look for signs of signal degradation like ringing, distortion, or excessive attenuation, which can corrupt data or hinder circuit operation.

- System Stability: Frequent crashes, resets, or unexplained system instability can sometimes point towards underlying SI problems.

Catching these warning signs early can prevent bigger problems later on for your electronics!

Measurement Tools for SI Diagnosis:

Once you suspect an SI issue, it’s time to get a closer look. Here are some key measurement tools that can help diagnose the problem:

- Oscilloscopes: As discussed earlier, Oscilloscopes allow you to see the ups and downs, or voltage changes, of electrical signals in real-time. These are helpful in spotting problems like ringing (extra wiggles), overshooting (signal going too high), undershooting (signal dipping too low), or crosstalk.

- Time Domain Reflectometry (TDR): TDR sends a quick burst of electricity down the wire and measures what bounces back. It ensures that the signals travel clearly and efficiently. Engineers who design electronic devices like high-speed computers or phones use TDR to spot issues like mismatched impedance or reflections that can mess up signal integrity.

The Takeaway: Keeping Your Electronic Designs Seamless

Imagine your electronic device as a bustling city. Information constantly flows between its components, carried by tiny electrical signals acting as silent messengers. Signal integrity (SI) is all about ensuring these signals travel clearly and efficiently, just like a smoothly functioning communication network. Good SI means the signals encounter minimal interference or weakening as they travel. This translates to reliable operation, accurate data processing, and predictable performance for your device.

By prioritizing SI throughout the design process, engineers can create robust and dependable electronic systems.

Stay in touch to get more news & updates on Hintinsider.Com!